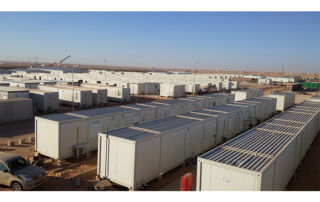

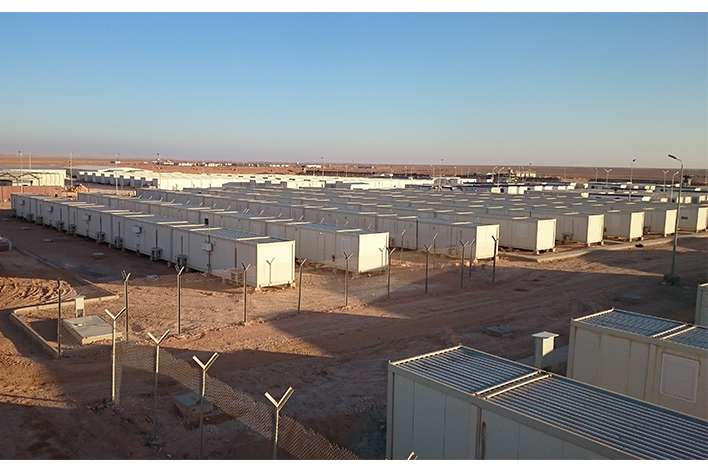

650-Person Prefabricated Modular Temporary Facilities and Integrated Camp Solutions within the Gas Field Development Project – Timimoun – Adrar – Algeria

Photo Gallery

Project Detail

Country

Algeria

Date

2015

Sector

Share Post

Information Request Form

An EPC Camp Solution Delivering Rapid Deployment, High Durability, and Operational Continuity Under Desert Conditions

The Timimoun Field Development Project, implemented in Algeria’s Adrar region, is a strategic energy investment aimed at increasing the country’s natural gas production capacity. Within this scope, prefabricated modular temporary living and operational support facilities for 650 personnel were delivered by Dorce under a turnkey EPC (Engineering, Procurement and Construction) model. The project was planned and implemented with full consideration of harsh desert climate conditions, remote logistics, and the stringent safety requirements of energy-sector operations.

The main contractor for the project was Samsung Engineering Company Limited, while the project owner was the GTIM Consortium, composed of Sonatrach, Total, and Cepsa. Fluor Corporation provided engineering management services. Dorce has been an active, locally registered company in Algeria for over 20 years, and has been a registered supplier to Sonatrach for more than 10 years.

An Industrial Camp Approach and Capacity

The temporary facilities constructed under the Timimoun Project were designed not only to provide accommodation, but also to secure operational continuity, safety, and logistics efficiency through an integrated camp concept. Serving approximately 650 personnel, the camp played a key role in supporting uninterrupted construction and commissioning works at the field site.

Structural Systems and Construction Technologies

The project utilized a hybrid building approach, combining:

• Modular steel buildings

• Light Gauge Steel systems

• Pre-Engineered Heavy Steel Structures

This system ensured rapid production and installation, while also delivering high structural durability and long-term operational performance.

Project metrics included:

• Total enclosed building area: 15,030 m²

• Total site development area: 81,270 m²

• Implementation period: February – July 2015

• Contract variation: November 2015

Thanks to modular design principles, the facilities were engineered to be relocatable and re-deployable, allowing dismantling, transport, and re-installation when required.

EPC Scope of Works

Under its end-to-end EPC model, Dorce undertook the full lifecycle of works, including:

• Engineering and implementation design

• Superstructure manufacturing and on-site assembly

• Electrical and mechanical (MEP) works

• Management of transport and customs processes

• Site installation and commissioning preparations

All works were executed in accordance with international standards specific to the oil and gas industry.

A Fast, Reliable, and Climate-Adapted Solution for Desert Conditions

Delivered in an environment characterized by extreme temperature variations, sandstorms, and remote logistics, the project clearly demonstrated the advantages of modular and steel construction technologies in terms of speed, durability, flexibility, and operational resilience.

The Timimoun Field Prefabricated Modular Temporary Facilities Project stands as a scalable and reliable reference for similar gas field development and expansion projects across North Africa.